Möbelstar

Although there are fierce debates about which is the better or more beautiful material for making pine furniture, this is mostly just a matter of belief. After all, the aesthetic appearance or quality of a product surprisingly depends more on the adherence to the production technology than on the type of pine wood.

The most common material for making pine furniture is planed pine. Its quality is already the basis for the quality of the finished furniture. The process of producing planed pine wood is as follows:

The pine that has been cut down and freed from its bark is sawn according to the needs of further use. At this time, the wood still contains a significant amount of water. The pine wood is therefore carefully dried. The cells of pine wood are hollow, so they can store a lot of water. This evaporates first. When the water in the cell walls is also removed, the wood begins to shrink. For indoor use, the moisture content of pine wood must be reduced to between 6-10%, which is achieved by using drying chambers. Depending on the type of pine wood and the current moisture content, drying must be carried out extremely carefully. After this, the pine wood “strips” set to the same size are fitted together by a machine, gluing them together in the process. They are pressed and cut into standard-sized boards and packaged. These can later be purchased in stores and cut to the desired size for use.

Current catalog is available here >>>

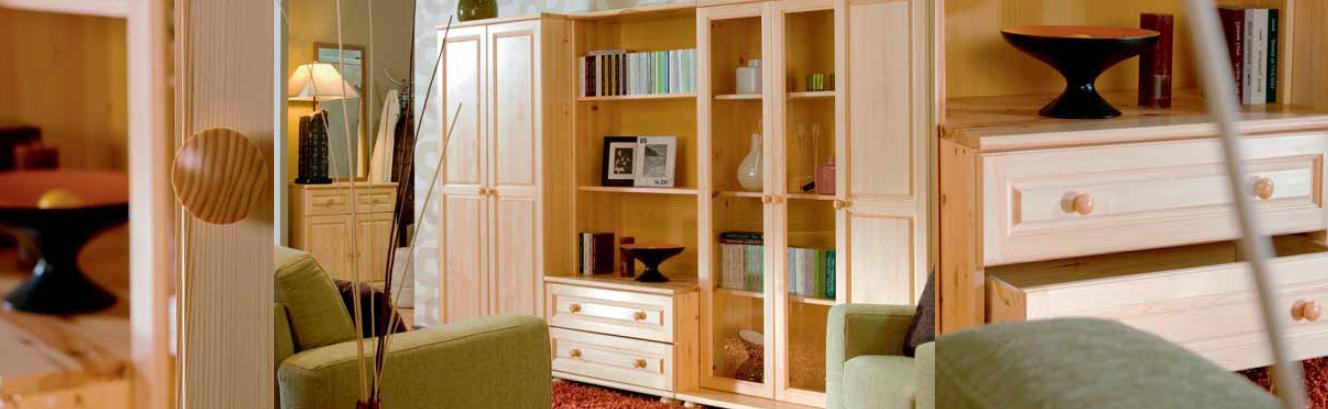

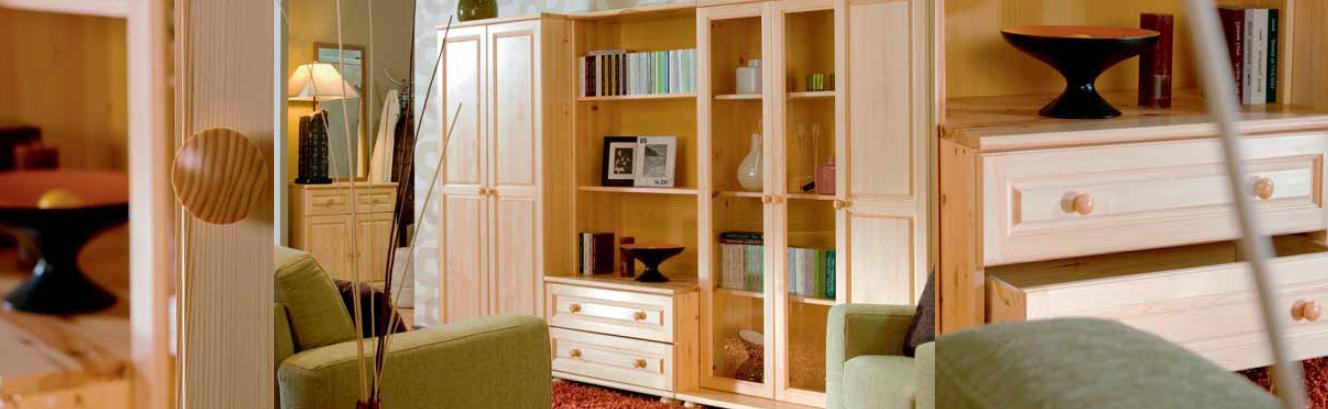

Möbelstar knows exactly that choosing furniture is a long-term decision. Their products include cabinets, chests of drawers, beds and other accessories. The carefully selected raw materials and the detailed workmanship make their furniture unique.

The company's business policy is to offer quality products at affordable prices! Pine bed frames and furniture are very popular, as pine wood is a light and durable wood.

Here are some general opinions and characteristics about pine wood:

Durability: Pine wood is considered a high-quality and durable material, which makes it means that bed frames and furniture can have a long lifespan. If they are properly cared for and regularly maintained, they can retain their original condition for a long time.

Natural look: Bed frames and furniture often have a simple and clean design, which creates a natural and pleasant atmosphere in the bedroom or other rooms.

Paintability: Pine wood takes paint well, so you can personalize your furniture. If you want to give your bed frames or furniture a different color or style, you can easily paint or stain them.

Affordability: Pine wood is generally in the mid-range price range, which means that bed frames and furniture are available at an affordable price. This wood can be a good alternative to more expensive wood types without having to compromise on quality.

In Europe, the two most common pine types used in the furniture industry are spruce and pine.

Although there are fierce debates about which is the better or more beautiful material for making pine furniture, this is mostly just a matter of belief. After all, the aesthetic appearance or quality of a product surprisingly depends more on the adherence to the production technology than on the type of pine wood.

The most common material for making pine furniture is planed pine. Its quality is already the basis for the quality of the finished furniture. The process of producing planed pine wood is as follows:

The pine that has been cut down and freed from its bark is sawn according to the needs of further use. At this time, the wood still contains a significant amount of water. The pine wood is therefore carefully dried. The cells of pine wood are hollow, so they can store a lot of water. This evaporates first. When the water in the cell walls is also removed, the wood begins to shrink. For indoor use, the moisture content of pine wood must be reduced to between 6-10%, which is achieved by using drying chambers. Depending on the type of pine wood and the current moisture content, drying must be carried out extremely carefully. After this, the pine wood “strips” set to the same size are fitted together by a machine, gluing them together in the process. They are pressed and cut into standard-sized boards and packaged. These can later be purchased in stores and cut to the desired size for use.